In this article I will talk briefly about each of the elements of Supply Chain Planning, In future articles I will go on to look in more detail at each. The elements I want to cover here are:

- Demand Planning,

- Activity Planning

- Launch Planning

- Supply Planning,

- Capacity Planning,

- Production Planning,

- Labour Planning and

- Materials Planning.

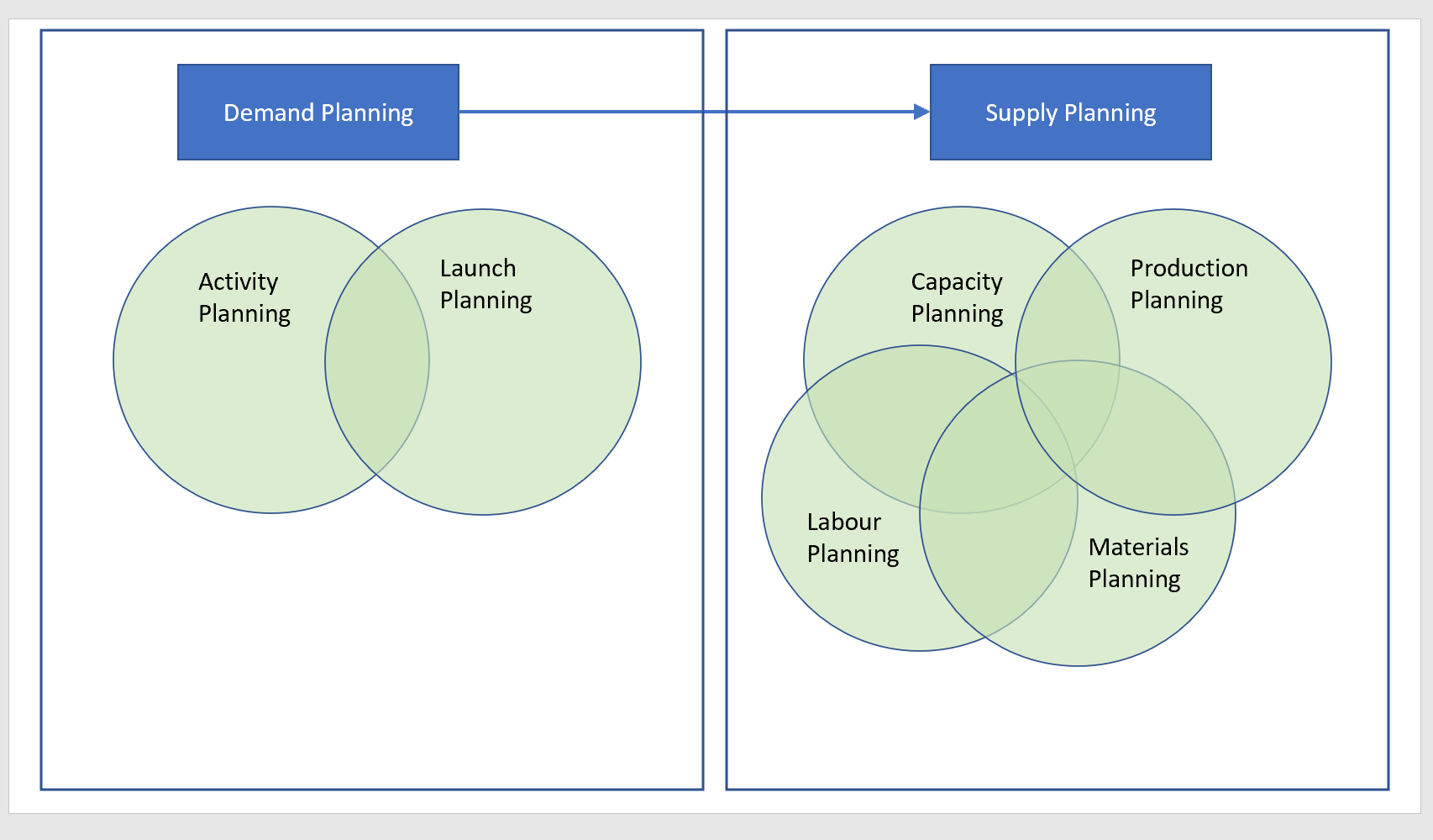

Some of these are subordinate to others and there is significant overlap between others. Fig 1 shows the relationship between each element.

So the two key pillars are Demand Planning and Supply Planning and these are each supported by overlapping elements.

Let's begin by looking at Demand Planning

First of all we should differentiate Demand Planning from Forecasting. There are "official" definitions but my own interpretation of these is that:

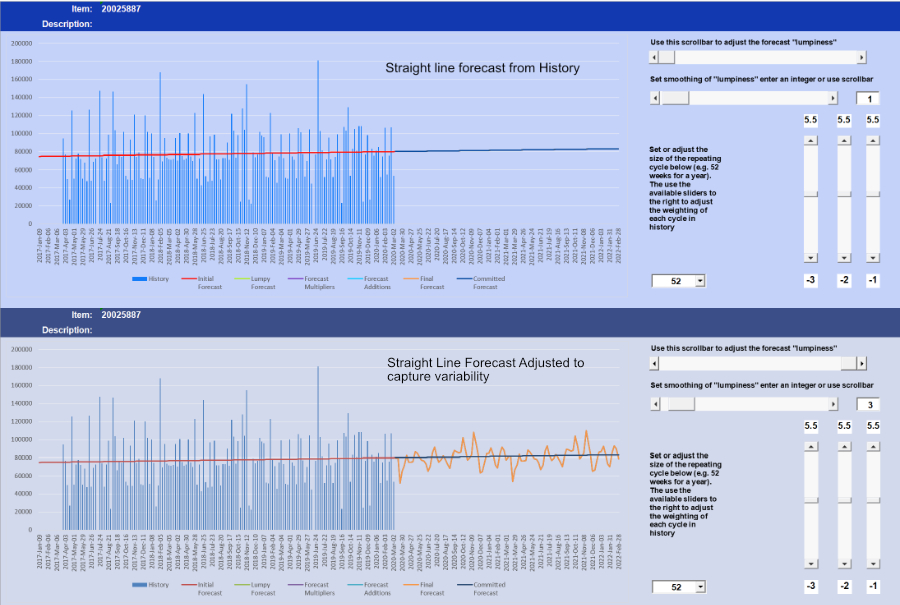

Forecasting is the science of extrapolating from historic data into the future. There are many systems which focus on this and many statistical algorithms which attempt to improve precision of forecast. My own view is that businesses can spend too much time, money and effort on this exercise with diminishing returns.

Fig 2. shows a very simple straight line forecast alongside one where variability has been included. (Using Simple Forecasting - click to open information in a new window)

My question would be how much value is added by adding the variability? How much is it likely to be repeated in the future? Without doubt there can be value in broad seasonality (Christmas or seasonal uplifts for example) but I would argue that the improvement in accuracy beyond that is often minimal.

And so we move on to Demand Planning, as per my differentiation between forecast and plan in my previous article a plan is a series of actions you intend to make happen whereas forecasting is simply an extrapolation of history.

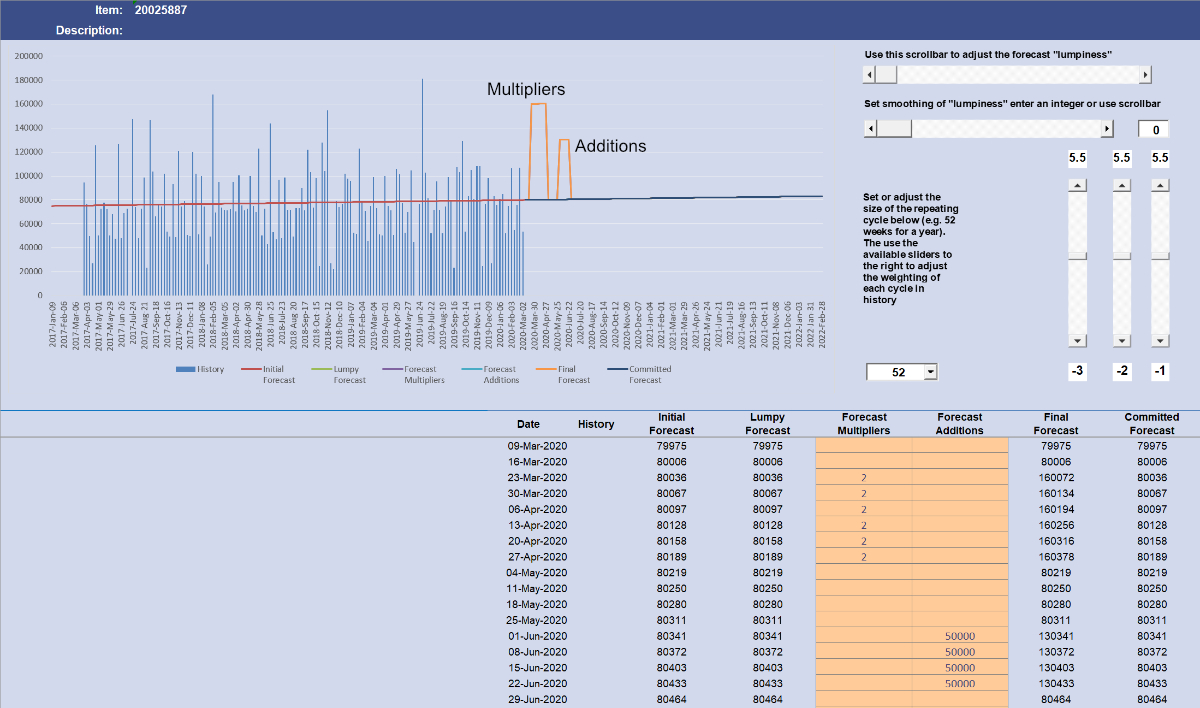

In Fig 3 we can see the effect of adding into the system the impact of specific planned actions.

I will cover all of this in more detail in future articles but for now let's move on to -

Supply Planning

Supply Planning covers several overlapping functions all of which though stem from planning the production required to meet the demand from the Demand Planning function.

Once that production is planned on a just in time basis then it will become apparent where there are machine capacity or labour capacity and material supply issues. These need to be corrected either by providing more capacity as needed or by moving production forward to put down inventory to smooth production whilst meeting demand. Of course shelf life is a key constraint here as is demand variability and the risk of obsolescence. All of these factors should be taken into account to arrive at the optimum capacity fitted plan. In Veloc we call these the Optimisation algorithms, we firmly believe these should be separated from the initial Infinite Capacity Plan so that the planner can see both.

As a final step if a capable plan cannot be achieved via the above it may be possible to make the final fit by accepting some risk to supply by reducing safety stocks for a period of time. In Veloc we call these the Recovery or trimming algorithms - they should only ever be used AFTER Optimisation.

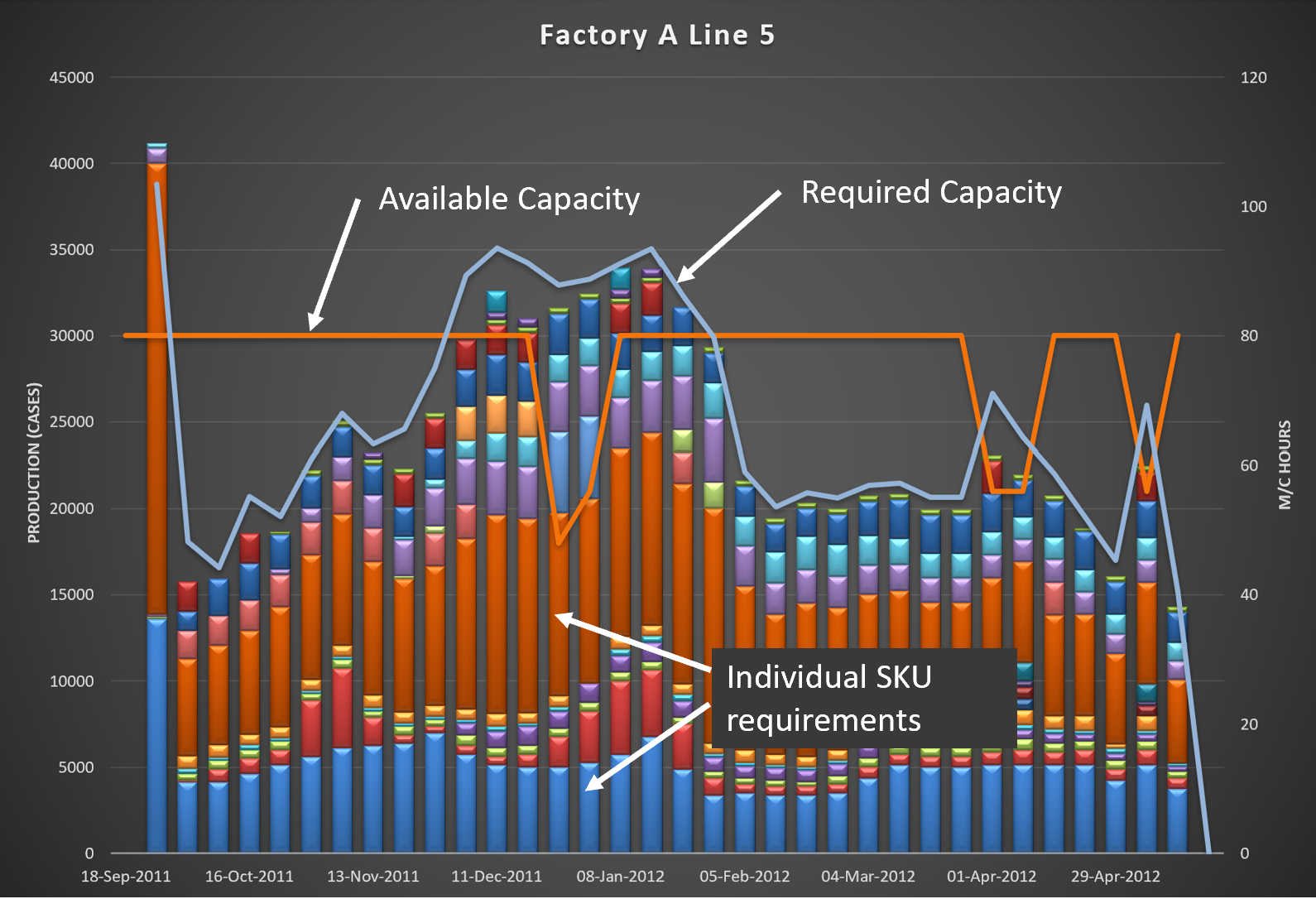

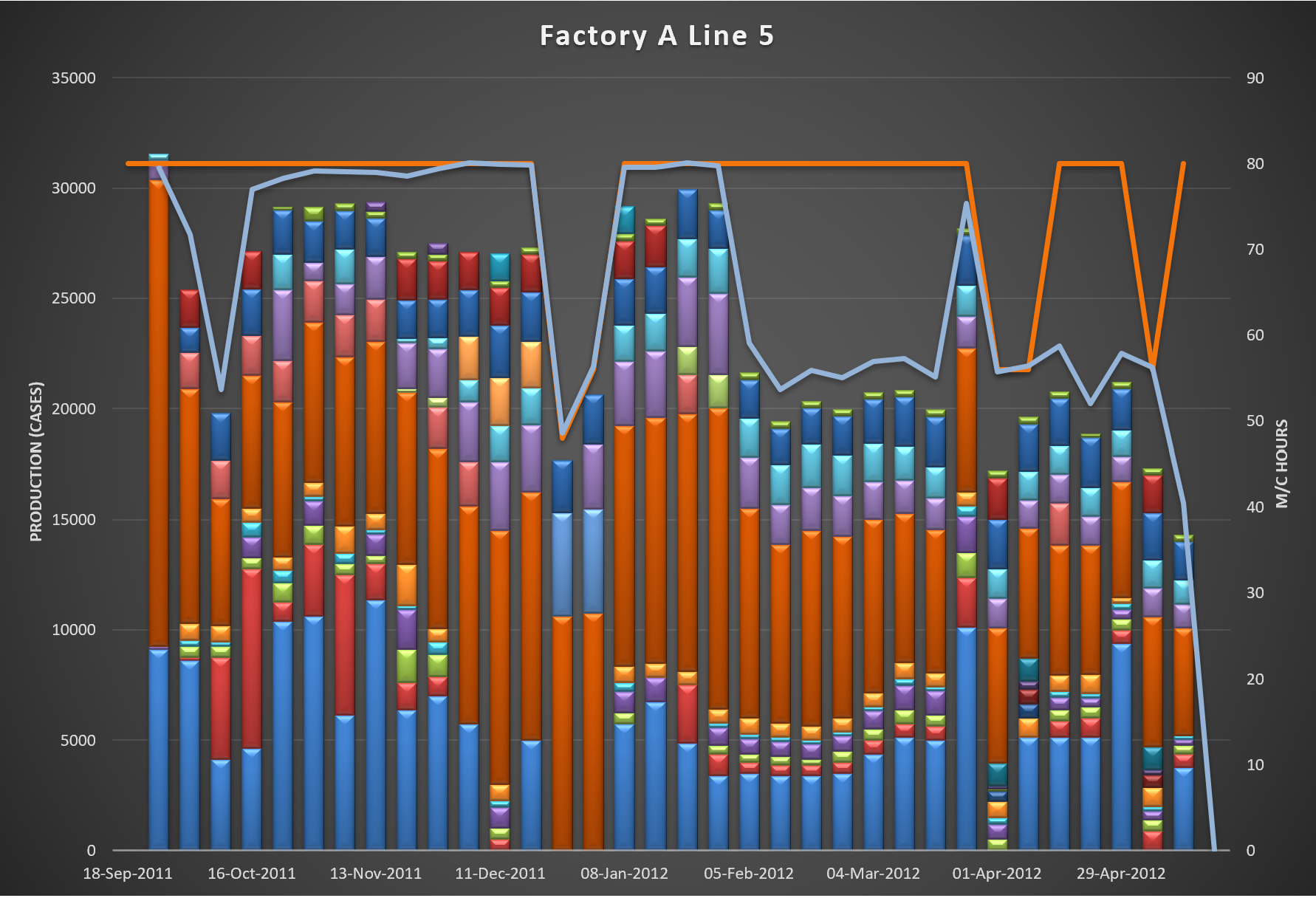

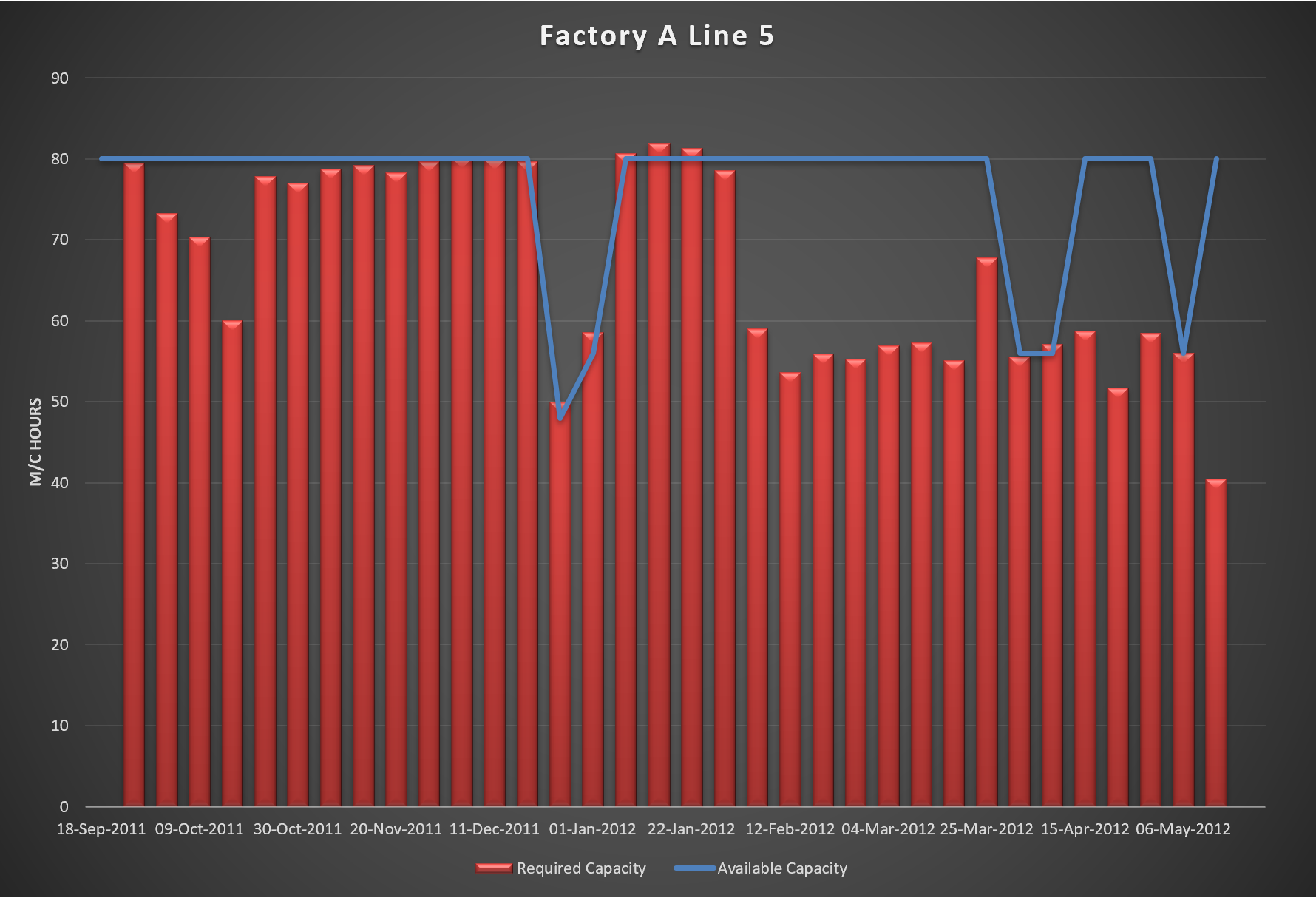

Figs 4 and then 5 here shows an infinite capacity plan and the fitted finite capacity plan after both Optimisation and Recovery algorithms.

| Fig 4. Infinite Capacity Plan | Fig 5. Plan after Optimisation and Recovery |

|

|

If even after all of this the plan cannot be achieved then it will be necessary to go back to sales and marketing to agree changes to the demand plan. These change must be as a result of changed actions - changing the forecast without changed actions is simply creating a fiction.

So Capacity Planning, Labour Planning and Materials Planning are part of Production Planning - the 4 elements are inseparable.

In many businesses still today all of the above is not carried out. Instead there is a crude attempt to manage capacity via something called Rough Cut Capacity Planning (RCCP) and then simply move on to short term scheduling.

RCCP was created in the days before significant computing power was available and it was the only way to get a view of the medium to long term requirements. Today ordinary desktops and laptops coupled with software such as Veloc can create fully detailed plans going out for several years in minutes! There is absolutely no need for RCCP. For sure the detail can sometimes get in the way but correcting that is simply a case of adjusting the delivery.

Fig 6 below shows exactly the same view as Fig 5 but this time showing only capacity not the detail of each planned production quantity.

Remember, though, this is a plan and the production quantities 10, 12 or 50 weeks out are unlikely to be what is really required at that point but they are the best estimate at this time and so for planning purposes can be used to look at Capacity, Labour and Materials requirements.

I would strongly advise that, if your software vendor is talking to you about RCCP, you ask them why. What is it about their product that is incapable of delivering a fully detailed plan and then showing only the elements you need.

In the next instalments I will focus in more detail on each of these elements in turn before going on to look at how planning should be used to drive S&OP/ IBP and other aspects of Supply Chain Management.

Comments powered by CComment