Dynamic Safety Stock

Dynamic Safety Stock means a safety stock setting which changes automatically depending on the demand signal. Many years ago (and, sadly, still today with some systems and in some businesses) safety stock was set as a fixed quantity. This is still true of most MRP/ERP based planning systems.

There are a number of advantages to dynamic safety stock:

- There is no need to manually adjust safety stocks as the demand signal changes.

- Well designed dynamic safety stock algorithms will ensure stocks are built in good time for uplifts

- dynamic safety stocks will automatically reduce to zero in time to avoid obsolescence when demand ceases.

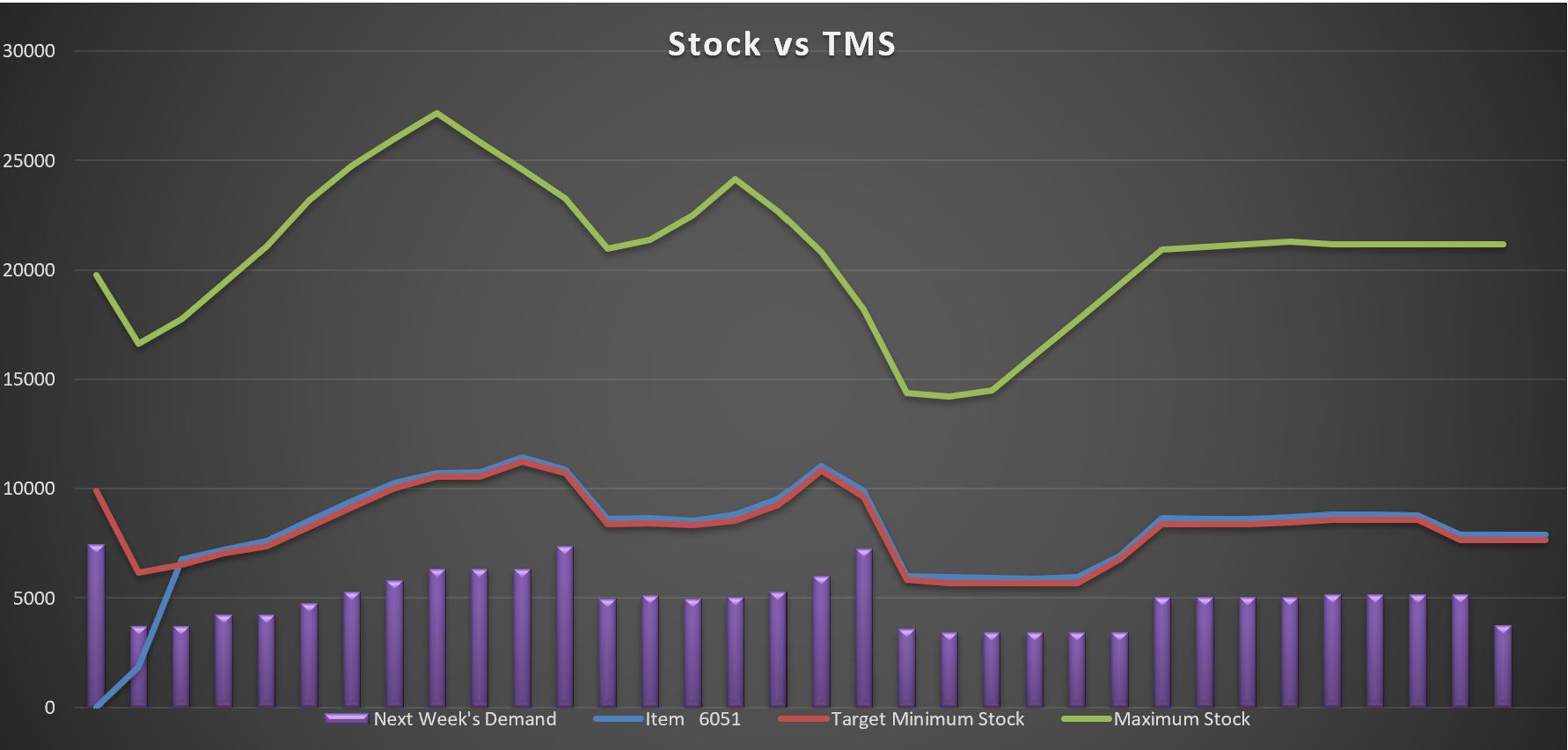

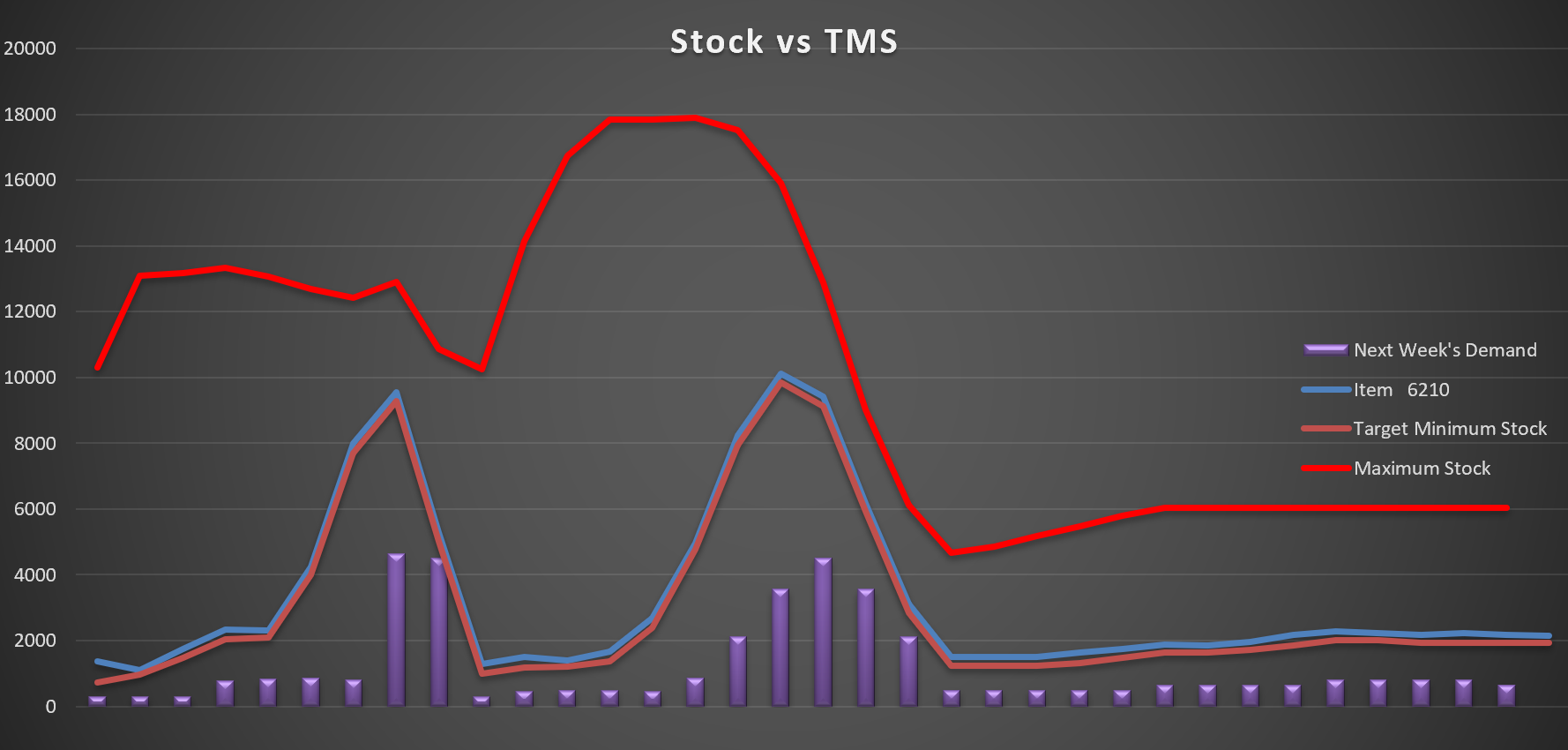

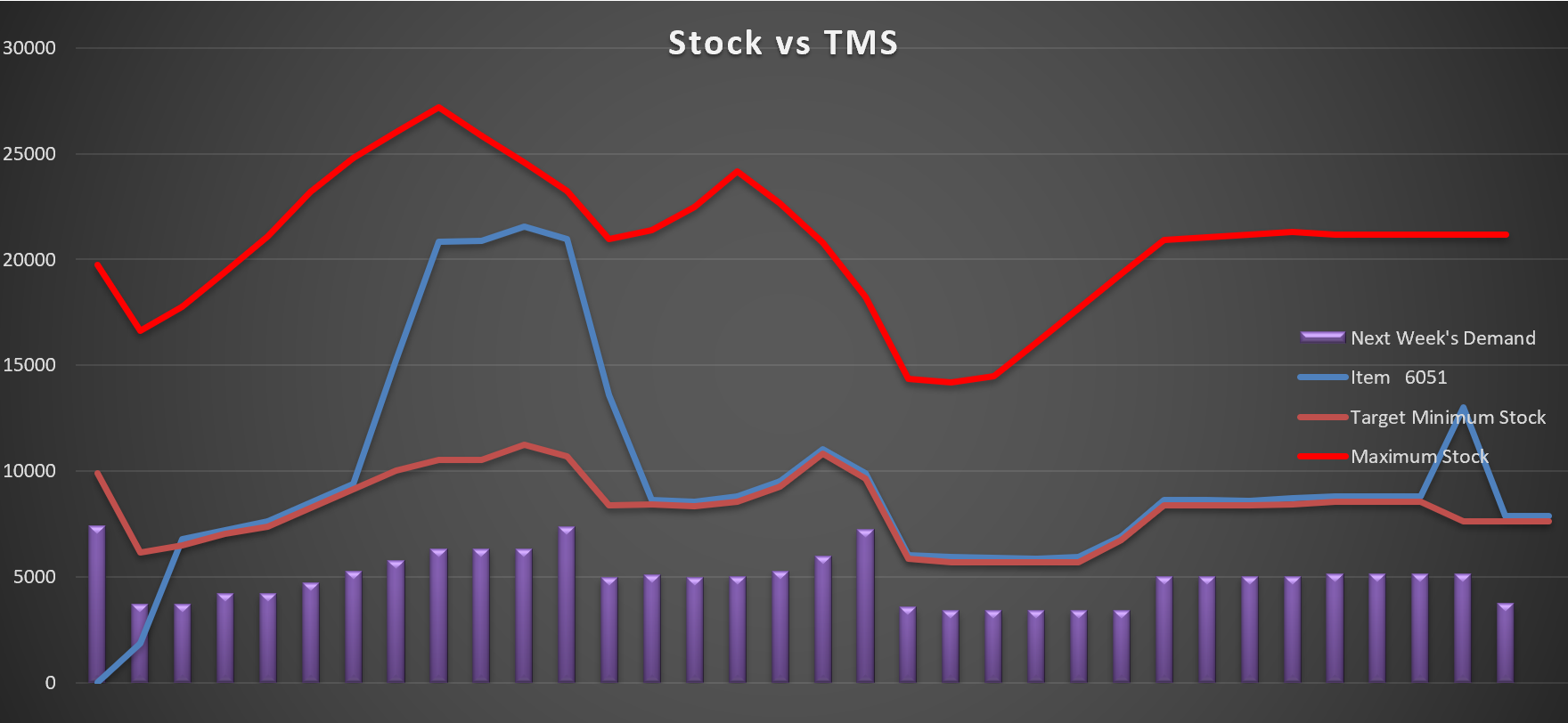

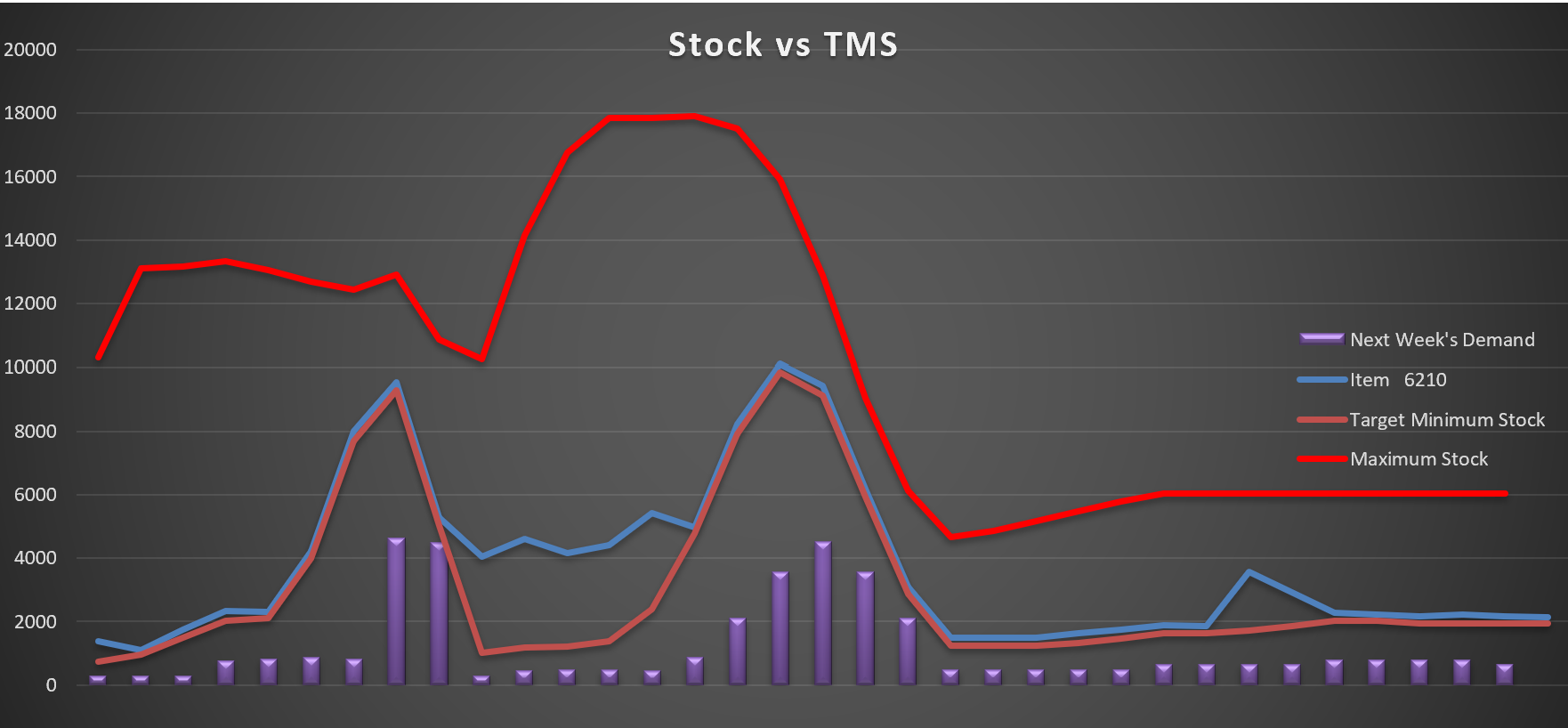

The Veloc planning system uses dynamic safety stocks expressed as days of cover required. The results of an initial plan using these parameters can be seen in Fig. 1 and Fig.2 . The delivered inventory remains very close to, but always above, the Target Minimum Stock or Safety stock. As you can see the Safety Stock levels follow the demand signal ensuring the right levels of inventory to maintain service as demand varies.

With Veloc you can also express maximum stock as days of life or MLOR and the system will also respect this parameter in the planning algorithm and maintain stock levels optimally between min and max and Figs 1 and 2 also show max stock varying with the demand signal.

Fig. 1 Inventory results from an initial plan using dynamic minimum and maximum stocks. Item 6051

Fig. 2 Inventory results from an initial plan using dynamic minimum and maximum stocks. Item 6210 - a much more variable SKU

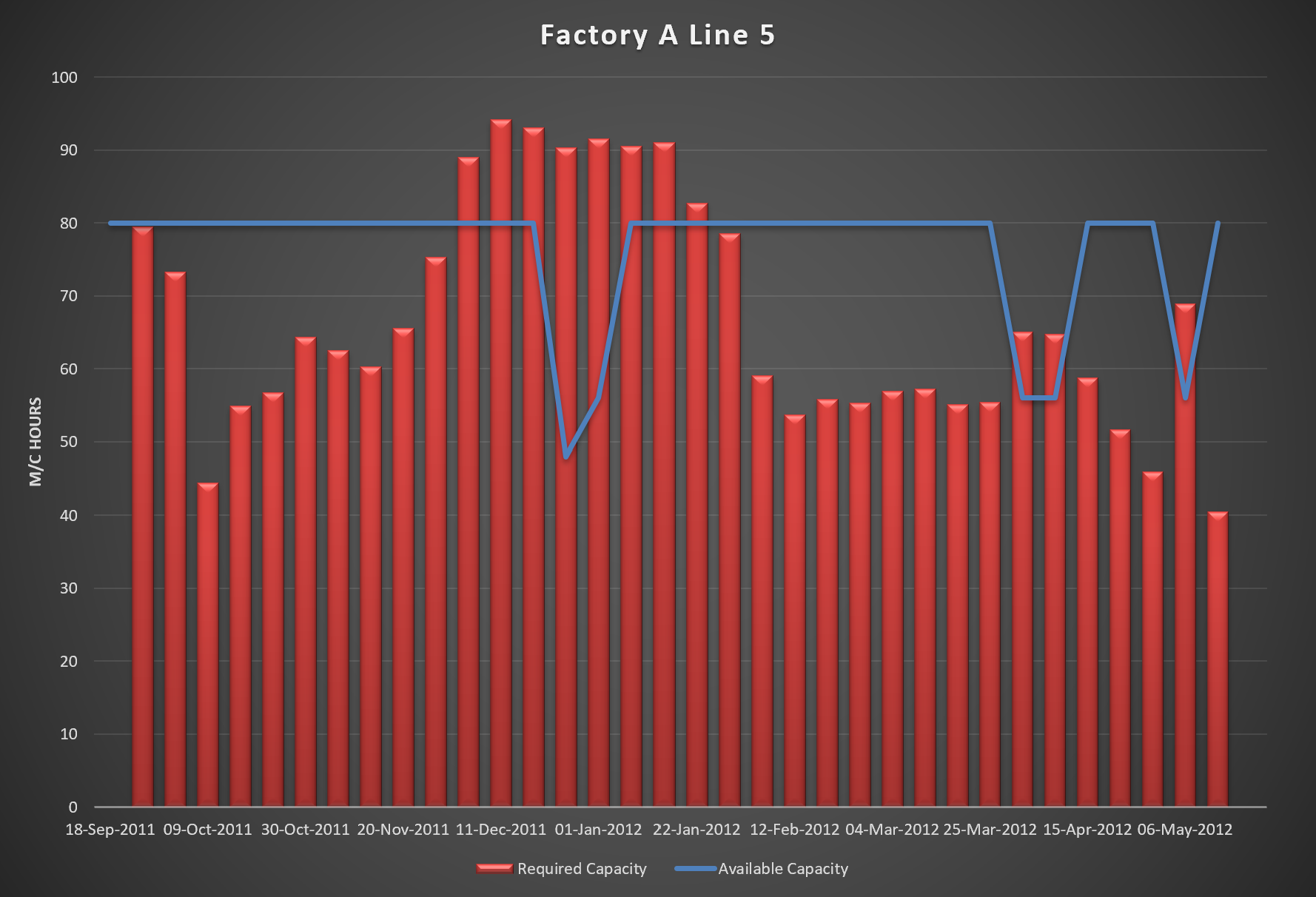

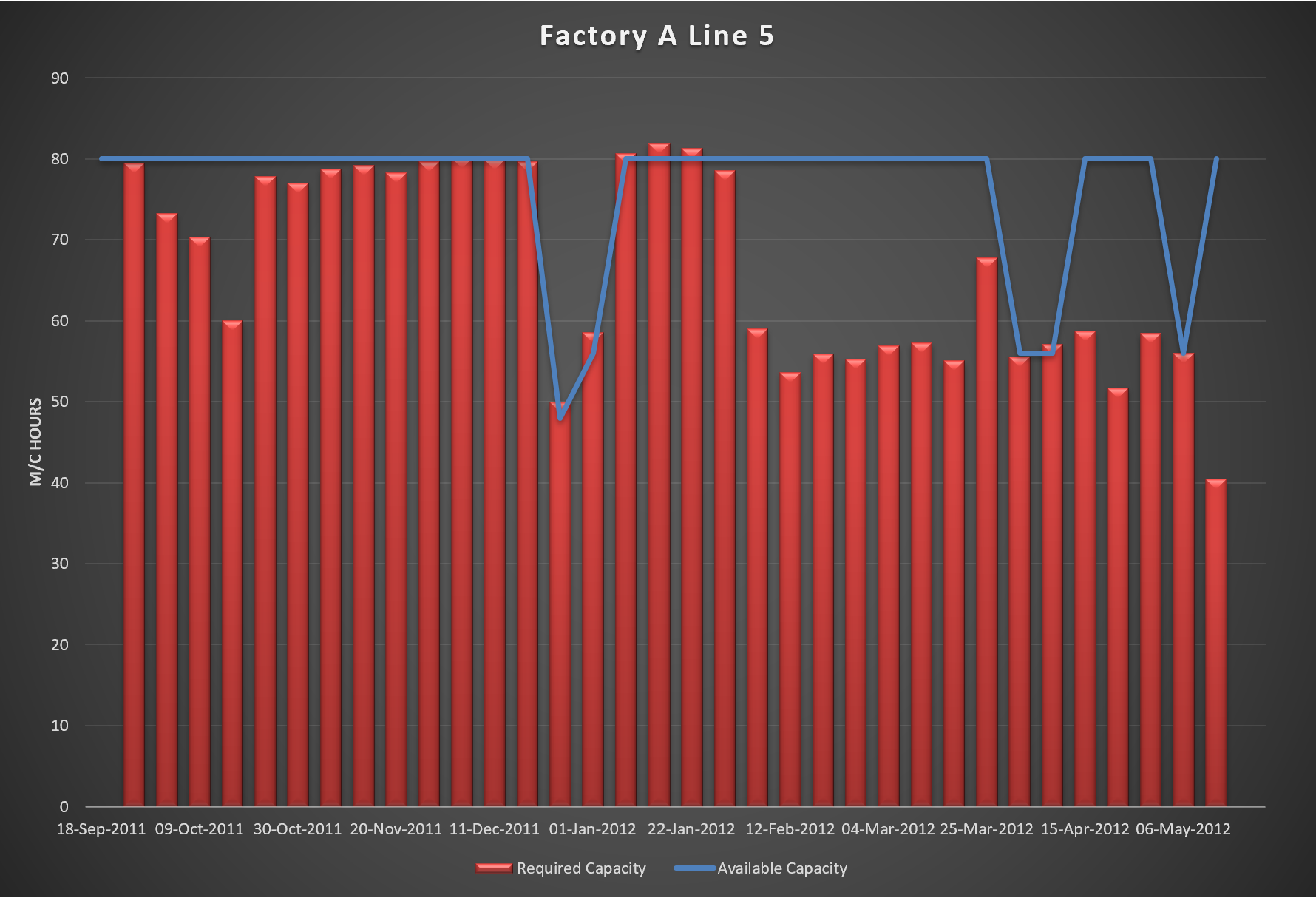

The above inventory results, though, are those before the Veloc Optimisation Algorithm has been enabled, as we can see in Fig. 3 the required capacity on this line exceeds the available capacity on several occasions. The Optimisation process will automatically correct this and smooth capacity (Fig. 4) - this part of the algorithm also fully respect dynamic safety stocks and the results can be seen in Figs. 5 and 6.

Fig. 3 Required (Red) and Available Capacity pre optimisation.

Fig 4. Required and Available Capacity post Optimisation.

Figs 5 and 6 Post Optimisation Inventory

As we can see from the two inventory charts above the optimisation has shifted some stock forward in time but always respecting both the dynamic minimum and the dynamic maximum.

The real game changer with Veloc is that this exact same logic is used throughout the Bill of Materials including components and right through to raws and packs. In this way we can deliver fully optimised MRP with dynamic buffer stocks similar but superior to those promoted by DDMRP.

Superior because we also incorporate forecasting and forecast consumption logic. (Another topic)

Comments powered by CComment