Immediate Capacity Shortfall - Prevention and Cure

Some days ago I posted this as a question here on #LinkedIn. There were some good answers and it provoked some debate. As is fairly normal these days it also prompted some replies from those advocating DDMRP but I don't intend to respond directly to those here, rather I will write separately on this topic.

Here I will set out how ways to avoid this dilemma and also how to deal with it if it does arise. I will specifically describe how #velocplanning can help.

Prevention or Cure

There are a huge number of reasons why a business might suddenly find itself in this situation:-

- A sudden and catastrophic breakdown

- Sudden loss of inventory (fire, flood etc.)

- Supplier product recall

- Sudden and un-forecastable demand (Covid19 = Toilet rolls)

It is right therefore that we have a properly constructed response plan - Cure. Simply saying "It shouldn't happen" doesn't cut it.

However, the most common reasons why businesses find themselves in this situation are poor demand planning, poor supply planning, denial, wishful thinking re output rates etc. and so it is also correct to focus on Prevention.

Prevention

The key to prevention of immediate capacity shortfall is to see it coming before it arrives and this involves good systems and good processes. The starting point is robust, well managed Demand Planning, not just forecasting (although that's where it starts).

Good Demand Planning takes a forecast (a projection of historic demand looking forwards with perhaps some seasonality and an overlying trend) and adds to it robust, bottom up, detailed, SKU and customer level plans and resulting demand changes. The process should then also involve frequent ratification and checking. S&OP/IBP with it's routine of continual verification of the fidelity of the plan and taking corrective action where required provides a process to do this. (my Review - Track - Plan approach - https://www.linkedin.com/pulse/implementing-sop-ibp-steve-allanson/).

In my experience a well constructed Demand Management process CAN yield good quality SKU level demand plans meaning that you can see demand spikes coming in good time - and can therefore plan a timely response through the inbound supply chain.

For a robust response it is essential to have in place a good capacity planning system and process which allows timely management of future demand uplifts using the best combination of planned capacity increase, planned inventory uplift and of course utilising dynamic safety stock adjustment throughout the supply chain. For the latter to work of course a good demand plan at SKU/Customer level is essential. Demand planning or forecasting solely at high level (as advocated by DDMRP) only allows for the capacity increase option unless inventory and buffer increase is randomly spread across SKUs.

Correct capacity planning through the whole supply chain (or down the B.O.M.) is also essential and this is where traditional MRP systems can be weak as their ability to look far ahead is often limited. MRP based solely on actual demand stands no chance!

Finally it is essential that the planning system allows for automated balancing, stock builds etc. as well as providing good visibility. Too many planning systems -

a. mix up the schedule view and the planning view making it difficult to see the broad picture and decide what actions to take

and/or

b. do not have good quality automated algorithms and so rely on the planner manually making what can be many hundreds or even thousands of adjustments.

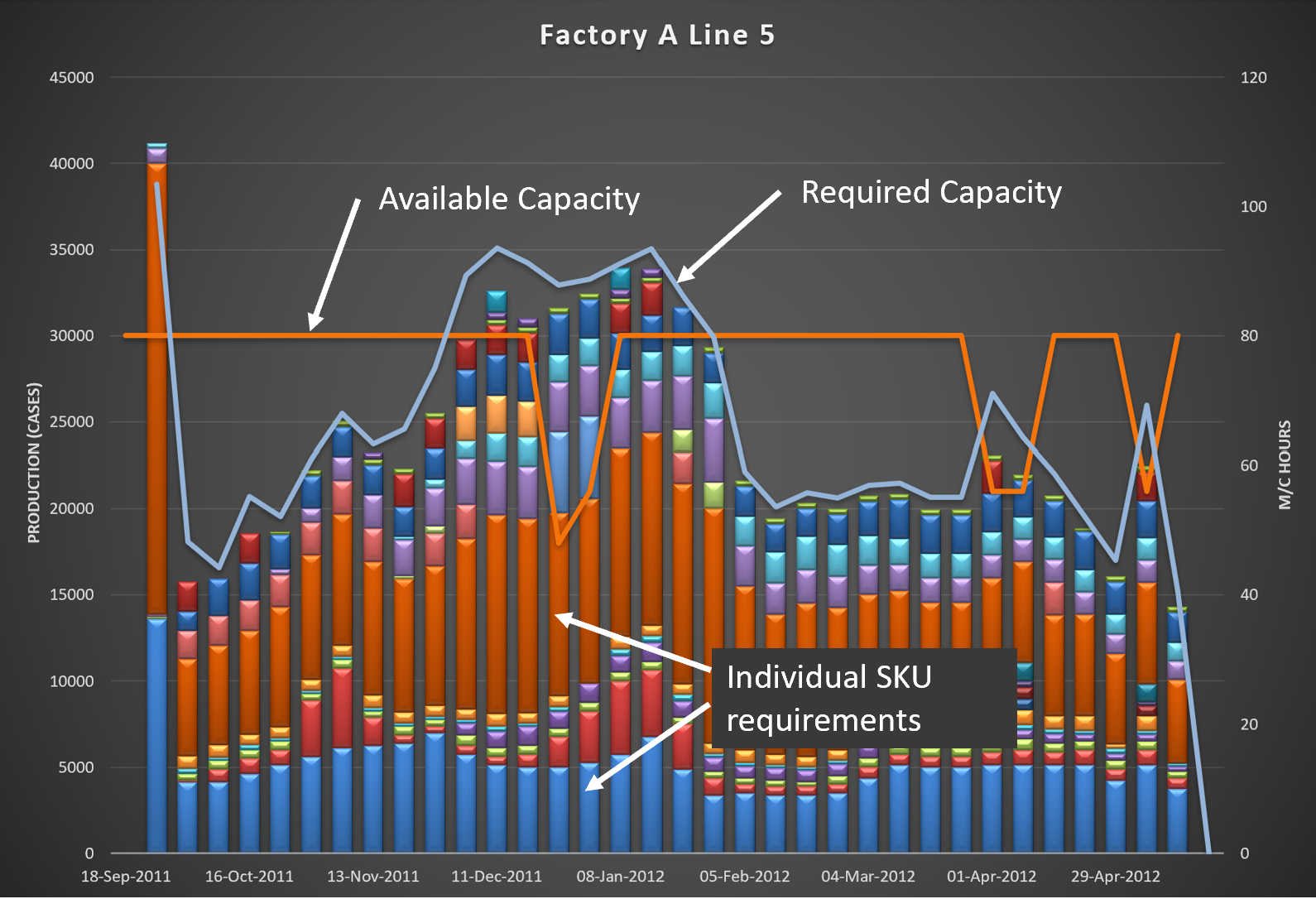

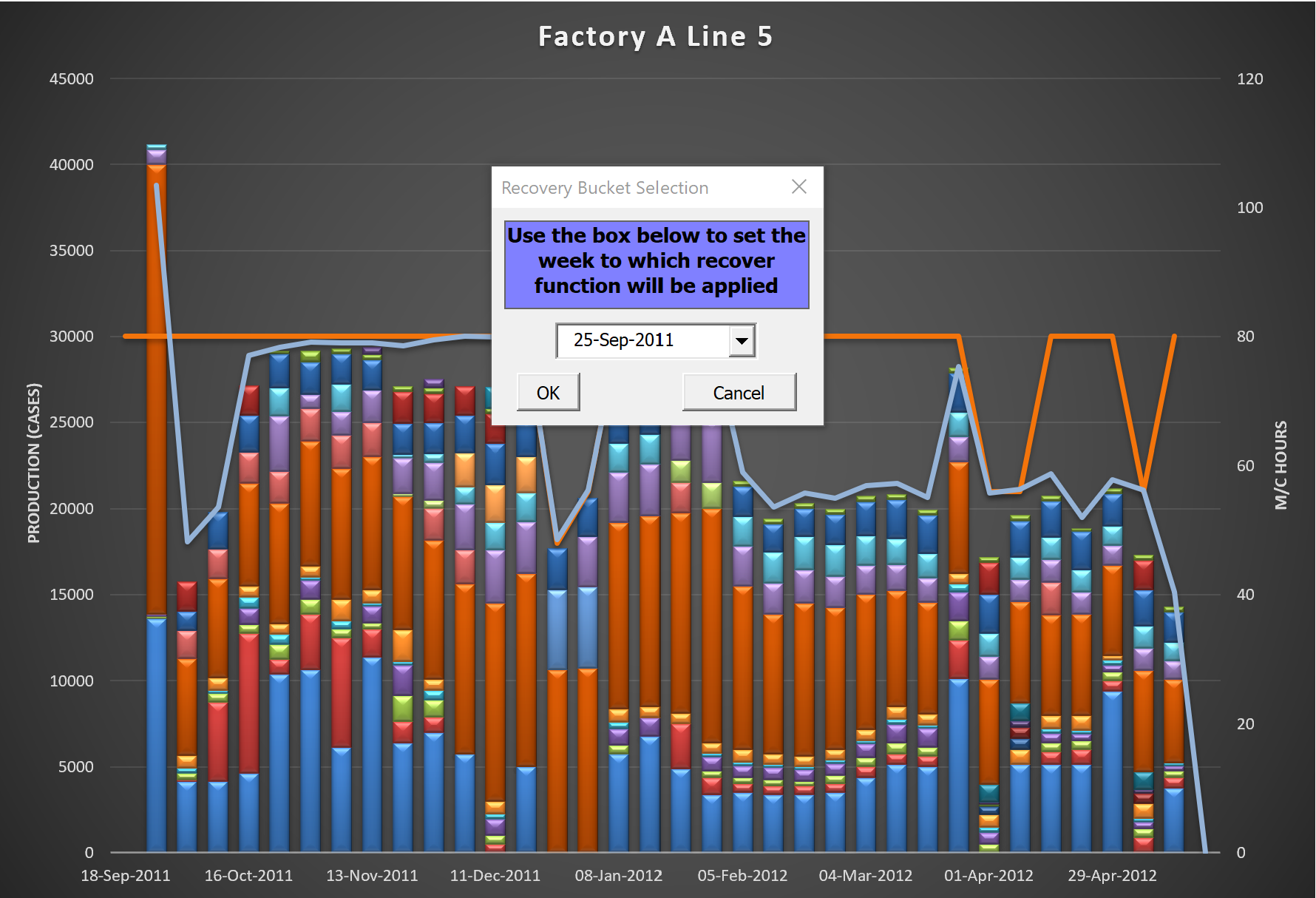

The Veloc Planning system not only provides well structured capacity views (such as in the header of this article) it also allows adjustment of the level of detail so that individual SKU contributions can be seen. (Levels of detail of all SKUs including volume, run time, planning rules, projected inventory are all available on the same screen using a combination of hover, right click and left click).

Chart 1 - un-optimised capacity view.

Available capacity can also be adjusted simply and easily (when agreed with manufacturing) without leaving this screen.

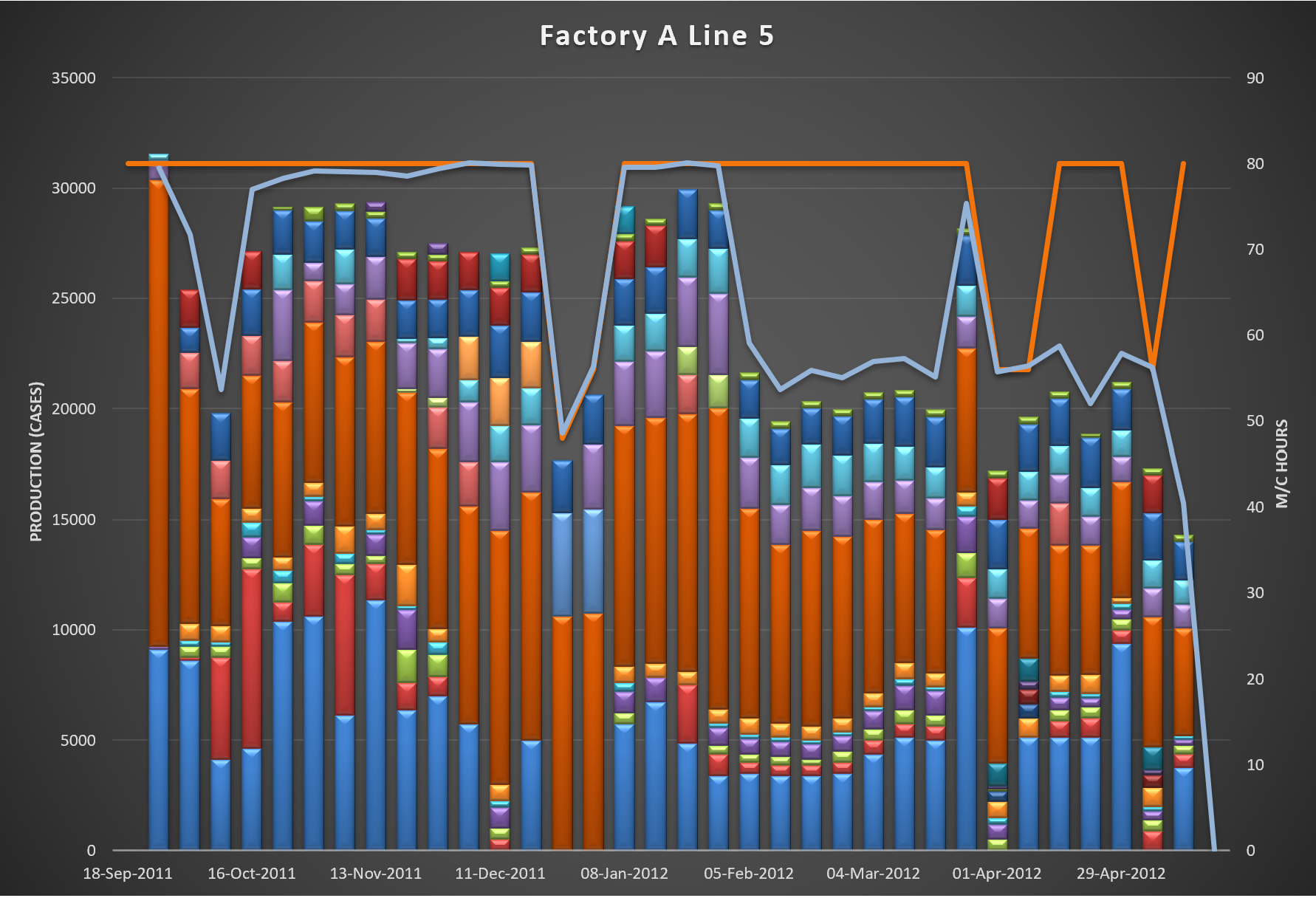

Finally the system provides a full Finite Capacity Algorithm allowing for adjustment of production volumes, and therefore inventory, across different resources (internal or external) and along the time axis. AND the optimisation flows all the way through the B.O.M. not only adjusting requirements at lower levels but also including adjustment of dynamic safety stocks and full capacity balancing where required. Dynamic buffer stocks through the B.O.M. ARE possible in a non DDMRP environment which allows for proper use of demand planning.

Chart 2 - Optimised capacity view.

Of course the future anticipated demand is not firm at this point so in reality all of the forward planning is only about reserving the right capacity unless intermediates and or raw materials and packs are long lead-time necessitating the placing of firm orders. Firm orders need only be placed when absolutely essential to respect lead-times. Good demand planning coupled with good finite capacity planning is wrongly characterised as "Forecast Push" - it is, rather, Demand Plan, Just in Time, Pull!

Cure

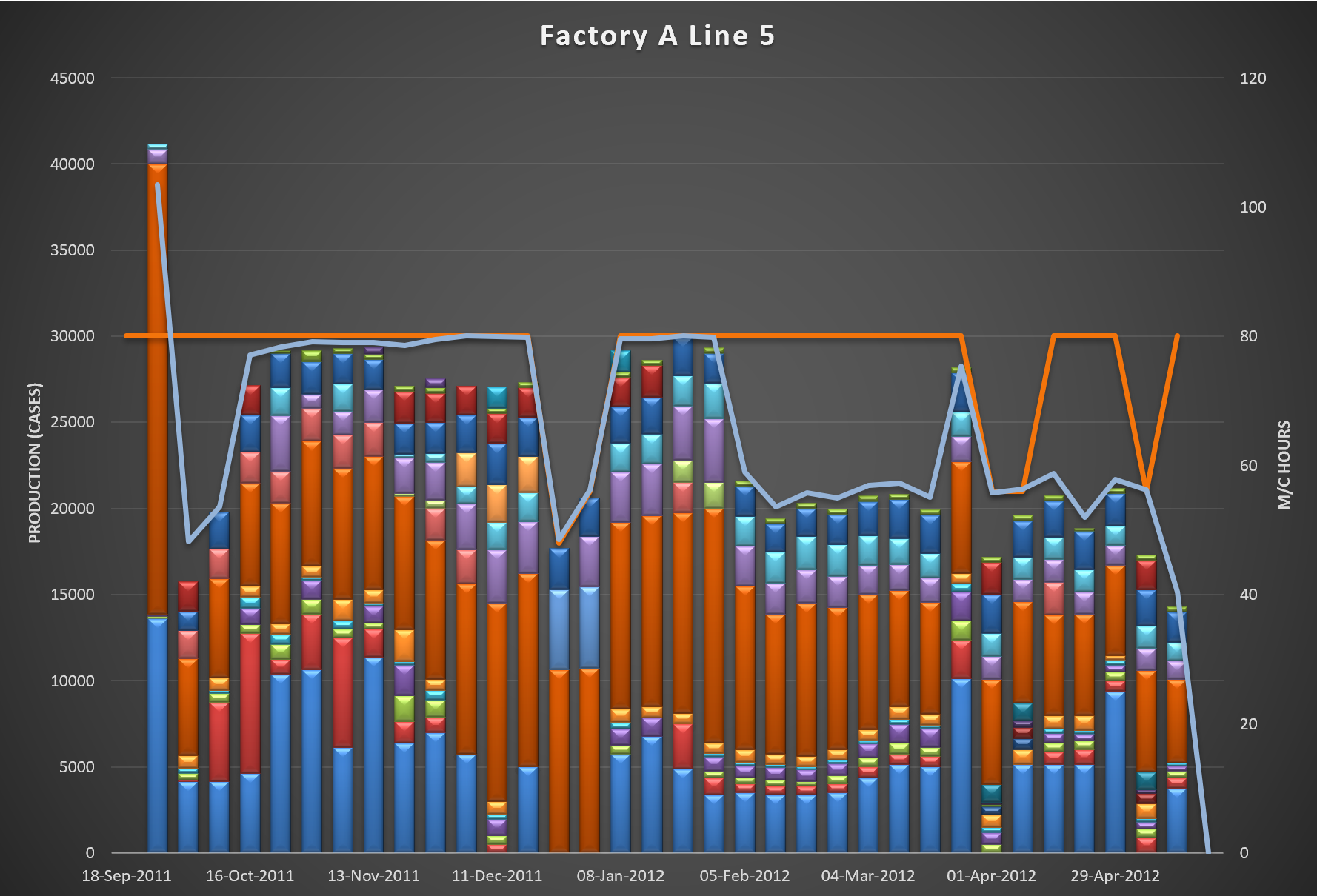

In chart 2 that only leaves the immediate capacity shortfall which might have been corrected by the Optimise algorithm by moving requirements to other available resources (internal or external) but in this case clearly has not been.

As some have said we need to explore first whether immediate capacity increase is available but in my experience this take some weeks (or even months) to bring on stream so that if such a situation does arise this does not offer a short term solution.

Clearly we need to trim production in the immediate horizon to fit available capacity - pretending otherwise and giving manufacturing untenable production plans will not work and in fact probable makes the situation worse by sending the wrong signals back to sales.

In many businesses (most?) it is left to the planner/ scheduler to decide what to trim and what not to trim - and without an overall plan of recovery. The situation is then just repeated the following week/ day etc. In addition it is often impossible to get sales and market people to agree, in the face of a crisis, whch SKUs/customer safety stocks are to be trimmed (or even in really severe cases which customers are going to be impacted).

The key, in my experience, is to pre-agree the hierarchy of risk to be applied SKU by SKU and customer by customer so that an algorithm can carry out the correction and provide an overall plan - not just of what to do now but also when the situation can be recovered.

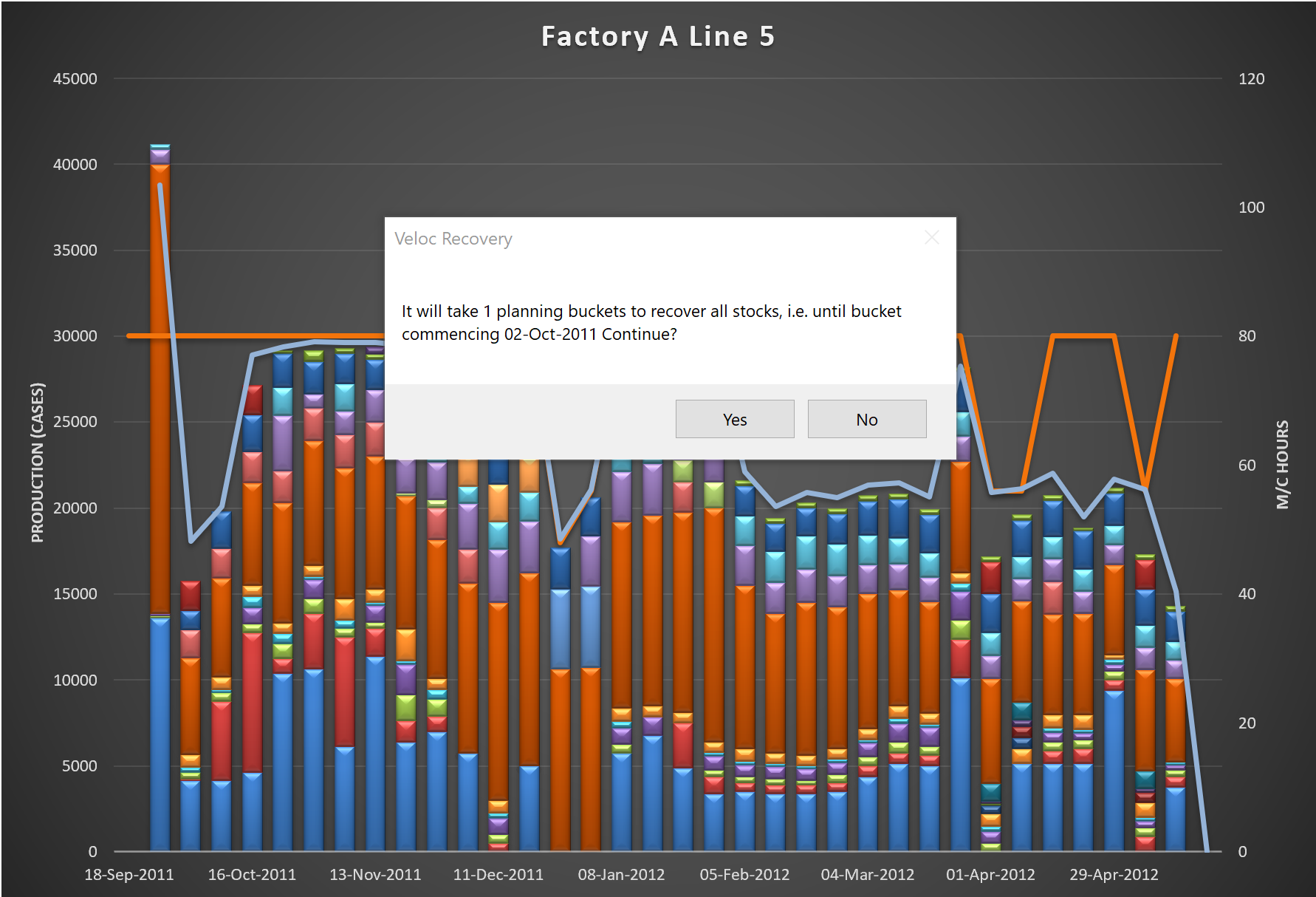

The Veloc "Recovery" algorithm does just this. It allows up to 3 levels of risk per SKU/Customer which are sequentially applied until the immediate situation is solved and then calculates a feasible recovery plan.

Clear visibility of immediate and short term risk is available to Sales for onward communication to customer. This provides confidence with the customer and prevents panic "buying" by them making the situation even worse.

AND - of course - all of this is cascaded through the B.O.M. - automatically correcting dynamic safety stocks and production/purchase plans.

Chart 3 - sequence of recovery in Veloc.

Conclusion

In Conclusion then we can see that robust Demand Planning and well constructed Finite Capacity Planning (extended throughout the B.O.M.) with dynamic safety stocks (again right through the B.O.M.) allows for both prevention and recovery of immediate capacity shortfalls.

Dogmatic application of any buzz word will not provide a robust solution. Detailed understanding can and will provide clear, concise and timely communication to the whole business of a thorough and complete plan of action.

Comments powered by CComment