Capacity Planning is something I have found many businesses, particularly short shelf life or predominantly make to order businesses, either don't do at all or do in a haphazard and/ or incomplete way.

Many years ago the ability to do capacity planning in a meaningful way was constrained by the availability of processing power, memory or (when I first began my career) the availability of a computer at all!

These days though this is simply not the case - the Veloc Planning System will plan a whole year of thousands of items all the way through the Bill of Materials in minutes - but many businesses still cling to the concept of Rough Cut Capacity Planning (RCCP) or avoid anything other than a very high level estimation on paper or a spreadsheet. Whilst some basic information can be gleaned from such a process in todays complex business, with many interdependent variables, it leaves significant risk of gaps and omissions.

Far better to use the available processing power to be able to build high level information on the foundation of detailed and accurate item level plans. Of course the ability to see these high level views is also important as otherwise it is likely the decision making will be mired in the detail.

So what do we mean by Capacity Planning?

Basically we need to define the available capacity of at least the critical rate or capacity limiting steps in the process of supplying customers and then assess how this is utilised to meet the projected demand ( Demand Planning ). The Capacity Planning process should allow us to see and resolve capacity issues and to understand the consequences of any movements away from just in time supply that are required.

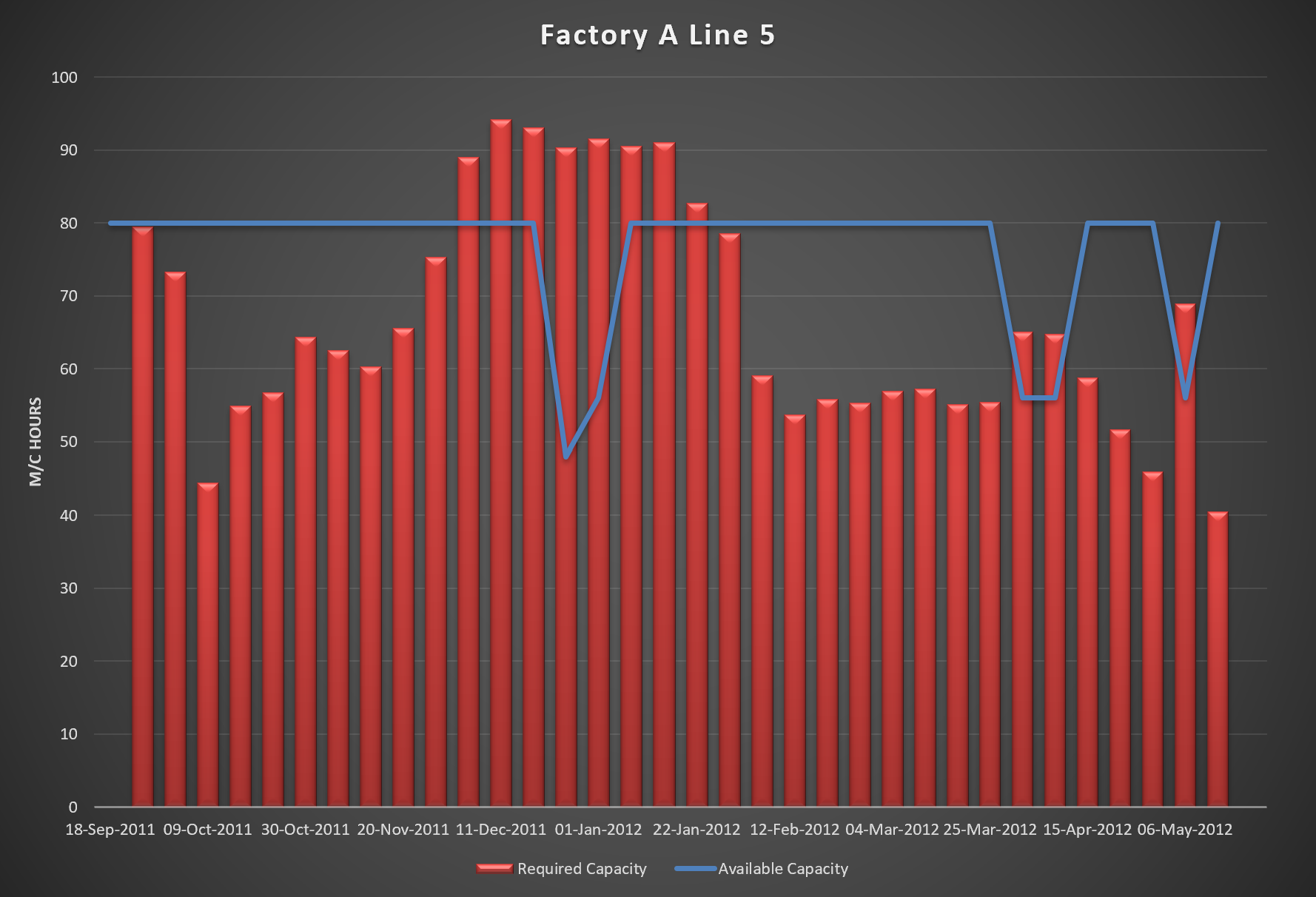

In fig 1 we can see that there are periods where capacity is underused on this resource and periods where there is a shortfall of capacity. The capacity planning process needs to address both of these.

Fig 1. The Blue line shows available capacity and the red bars required capacity.

So what can be done?

Well IF shelf life, storage space and cash flow allows we could move some production forward from the period around December and January into the period around October and November.

Veloc Planning will do this for you automatically in seconds respecting all shelf life, storage and cash flow constraints AND cascading the new demand right through the Bill of Materials.

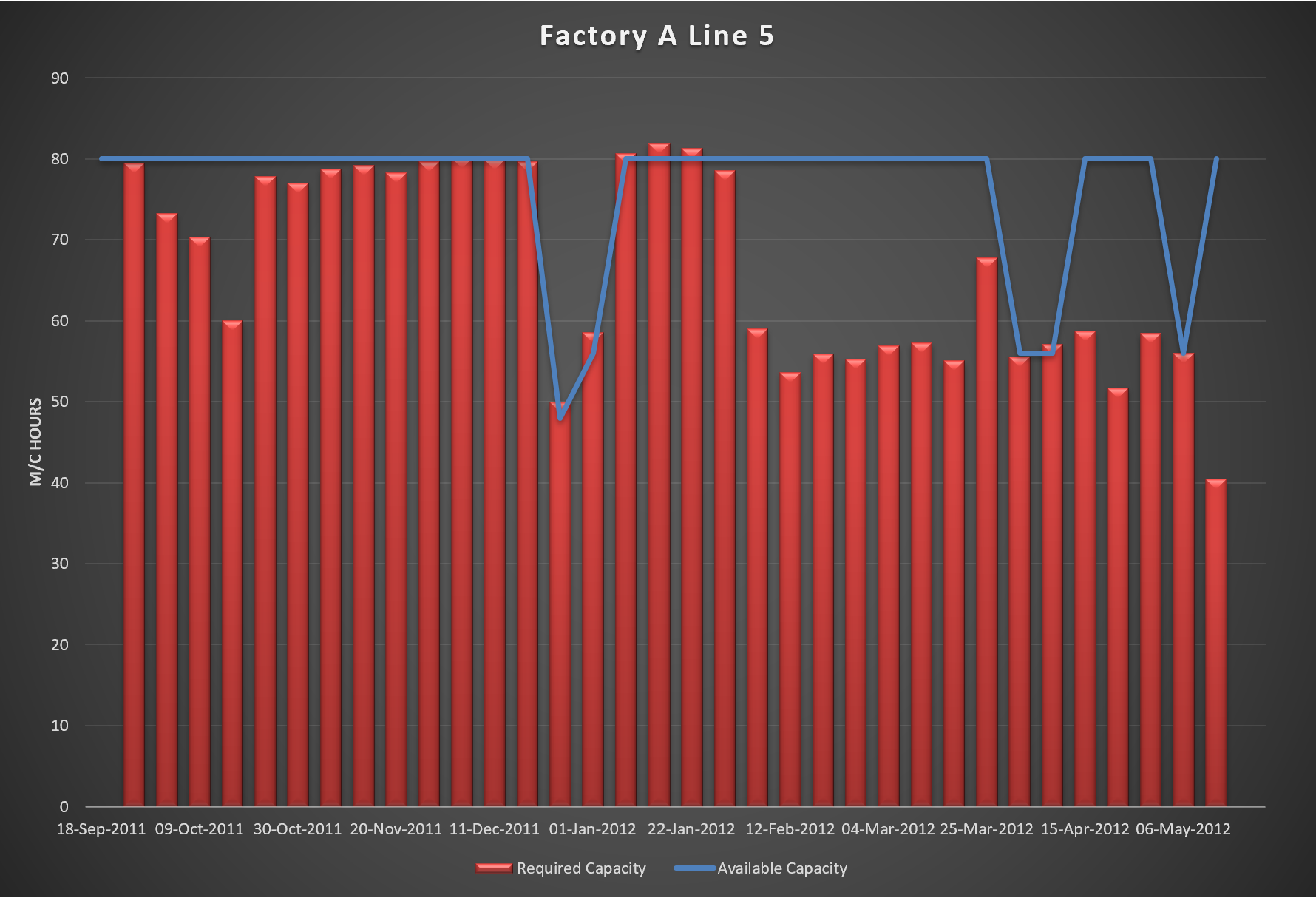

In Fig 2. we can see the resulting situation where now we have no periods where demand exceeds capacity. We have built inventory to cover.

In the latest 2023 version of Veloc this smoothing or optimisation can take account of not just manufacturing machine or labour capacity but additionally other constraints e.g. storage space or key raw material supply constarints.

And, of course, as the algorithms automatically cascade this plan right through the Bill of Materials we can see immediately what raw material ordering we need to action (and when) in order to support the the scenario. These can be immediately exported to the ERP system and communicated with suppliers.

This is Capacity Planning as it should be.

Comments powered by CComment